The Definitive Guide to Motorcycle Parts New Zealand Specialists

Table of ContentsSee This Report on Motorcycle Parts New Zealand SpecialistsThe Definitive Guide for Motorcycle Parts New Zealand Specialists9 Easy Facts About Motorcycle Parts New Zealand Specialists ExplainedThe Best Guide To Motorcycle Parts New Zealand SpecialistsFascination About Motorcycle Parts New Zealand SpecialistsSome Known Incorrect Statements About Motorcycle Parts New Zealand Specialists Not known Facts About Motorcycle Parts New Zealand SpecialistsThe 7-Minute Rule for Motorcycle Parts New Zealand Specialists

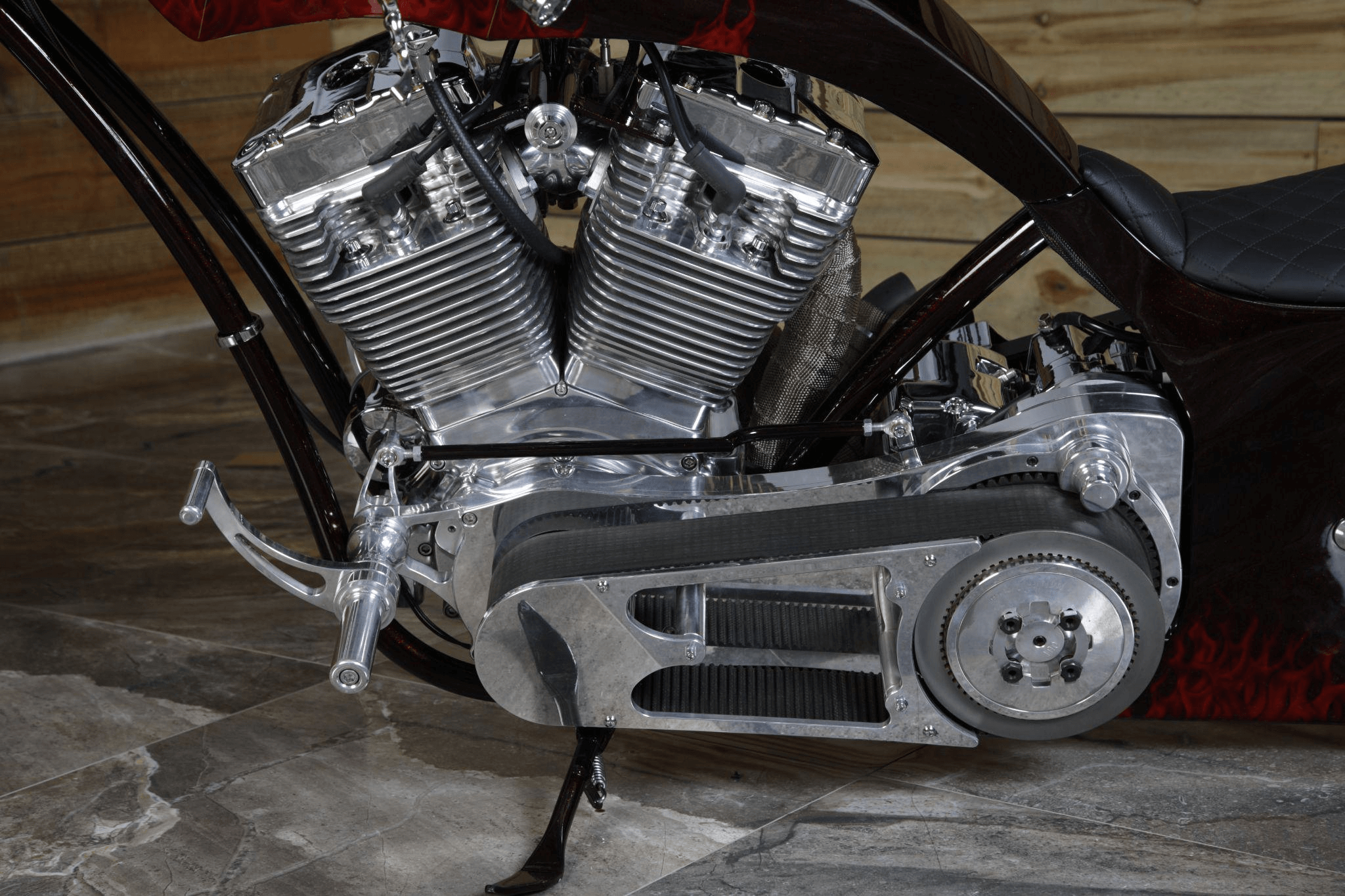

So, connect to among our professionals today.CNC machining modern technology is swiftly ending up being the focal factor of various production processes around the world as a direct outcome of its numerous benefits over various other approaches. Furthermore, the markets that manufacture motorbikes have actually hopped on board with this fad. The most cutting-edge business are currently creating their engine elements and wheels making use of machining techniques originally developed for motorbike parts.

On the other hand, the impacts of sector are the primary focus of this short article. Let's obtain straight right into it. You may be wondering why we utilize. It is not tough to fathom the aspects that led to this result. Currently that we have your focus let us describe the reasoning behind this modern advancement in the motorbike production industry.

The Basic Principles Of Motorcycle Parts New Zealand Specialists

Additionally, you have complete control over the appearance of the parts, even down to the min details. Periodically, motorcyclists might make a decision to fix up their ride by mounting aftermarket elements or modifying the bike's transformation. Once more, computer numerical control (CNC) machining is one of the most useful method. Upgrades may be of any kind of type and style you want.

Excitement About Motorcycle Parts New Zealand Specialists

CNC machining might be utilized to make almost all of a motorcycle's metal and plastic parts. To continue, we'll review several machined parts for motorbikes.

When personalizing the wheels, the disks are where the emphasis should be. Most of them are made out of aluminum. Light weight aluminum alloys are widely known for the impressive machining capacities that they possess. Milling treatments are used to get the wanted degree of wheel customization. An additional element of the motorbike that may be individualized is the tires.

Getting My Motorcycle Parts New Zealand Specialists To Work

When it pertains to an automobile (or a motorbike), one of the most crucial component is the engine. A number of people mention it as the "heart" of the vehicle. On the other hand, the camshaft, the cylinder head, and the pistons tend to be complex and call for designs with a high level of precision.

Usage only top quality products, however, because these lights are essential for the safety and security of motorcyclists and other chauffeurs or individuals on the road, particularly at evening. Motorbike headlights have three major parts: the bulb, or basics light source, the lens, and the real estate.

Milling processes with a flawless finish would certainly try this web-site cause the lenses having a reflective top quality that is similar to that of a mirror. The cover, on the various other hand, is not made up of fragile products; instead, it is built out of challenging polymers that can be machined right into even more detailed patterns.

See This Report on Motorcycle Parts New Zealand Specialists

They typically have fancy geometries with a riches of min details. Bike makers commonly cast these elements, but just for the production of bespoke parts. However, CNC machining is the technique of option when producing one-of-a-kind pieces. Machining on 5 axes in today's world is the means through which any style shape might be recognized.

Pick Runsom for your tailored motorbike components! We have the capacity to make complicated and stylish parts making your motorcycle incomparable.

Below are a couple of instances of steels commonly made use of in bike component machining. Aluminum is the primary product used by companies specializing in producing customized motorbike elements to produce most of these parts - Motorcycle Parts New Zealand Specialists.

Zinc describes one more metal that is extremely light in weight and has great machining high qualities because of its high mechanical strength. This product might be developed into practically any type of form and preserves its measurements well. Even mission-critical components that require a high degree of accuracy may take advantage of their use.

Rumored Buzz on Motorcycle Parts New Zealand Specialists

One more metal that sees hefty use in the production of CNC-customized parts is magnesium. It is among the lightest metals that are currently accessible and has exceptional machinability attributes and strength commensurate with its low weight. Among the downsides of magnesium is that its dust might easily ignite.

Their most common use in creating different motorcycle parts is bolts, such as screws and bolts. Their reduced vulnerability to oxidation and corrosion makes them ideal for this usage.

Not known Facts About Motorcycle Parts New Zealand Specialists

It seems that CNC turning and crushing are the fundamental processes. Alternative methods exist, such as exploration. Allow's investigate a number of these machining strategies comprehensive. The CNC turning technique is considered a subtractive production approach. On top of that, it needs keeping bars of material, most frequently plastic or steel, in setting and after that turning a reducing tool to eliminate areas of the product as the material is turned.

These approaches Full Article are equally crucial and generate elements with high precision and constant top quality. The processes help enhance the general quality of the machined motorbike parts.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists